Optimize Your US Import Supply Chain: Cut Lead Times by 15%

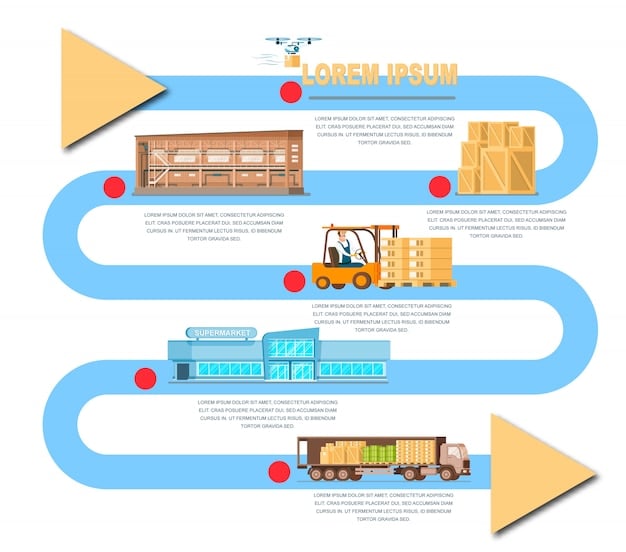

Optimize Your US Import Supply Chain: Reduce Lead Times by 15% with These Strategies by streamlining your processes can enhance efficiency, reduce delays, and improve overall profitability by reducing inventory costs, improving customer satisfaction, and gaining a competitive edge in the market.

Is your US import supply chain feeling sluggish? Discover how to optimize your US Import Supply Chain: Reduce Lead Times by 15% with These Strategies with strategic adjustments, improving efficiency and boosting your bottom line. Let’s dive in!

Understanding the Current State of Your US Import Supply Chain

Before embarking on optimization strategies, it’s essential to understand the current state of your US import supply chain. This involves a thorough assessment of existing processes, bottlenecks, and inefficiencies that contribute to longer lead times. Knowing where you stand is the first step toward making impactful improvements.

Assessing Current Lead Times

Start by meticulously tracking the time it takes for goods to move through each stage of your supply chain. This includes everything from order placement with overseas suppliers to final delivery to your customers in the US. Accurate data is the cornerstone of effective analysis.

Identifying Bottlenecks and Inefficiencies

Pinpoint the areas where delays commonly occur. Are there issues with customs clearance, port congestion, or internal handling processes? Understanding these pain points will help you focus your optimization efforts on the most critical areas.

- Reviewing historical data: Analyze past performance to identify recurring delays.

- Conducting process mapping: Visualize each step in the supply chain to highlight inefficiencies.

- Seeking feedback: Gather input from your team and partners involved in the import process.

By knowing these aspects of the import, you can start strategizing where to tackle the areas which need improvement.

Implementing Technology Solutions for Real-Time Visibility

In today’s fast-paced business environment, real-time visibility into your supply chain is no longer a luxury—it’s a necessity. Implementing technology solutions can significantly improve transparency, enabling you to proactively manage potential disruptions and optimize your US Import Supply Chain: Reduce Lead Times by 15% with These Strategies.

Leveraging Tracking and Monitoring Systems

Utilize advanced tracking technologies like GPS and RFID to monitor the location and status of your shipments in real-time. This allows you to anticipate potential delays and take corrective action promptly. These systems also provide valuable data for performance analysis.

Adopting Cloud-Based Supply Chain Management Platforms

Cloud-based platforms offer a central hub for managing all aspects of your supply chain, from sourcing to delivery. They facilitate collaboration among stakeholders, improve communication, and provide a comprehensive view of your operations.

- Improved data accuracy: Real-time updates reduce the risk of errors.

- Enhanced decision-making: Access to timely information empowers informed decisions.

- Better collaboration: Facilitates seamless communication among partners.

These platforms are the future for any company looking to improve their logistical business.

Negotiating Better Terms with Suppliers and Carriers

The relationships you maintain with your suppliers and carriers play a pivotal role in the efficiency of your US import supply chain. Negotiating favorable terms can lead to significant cost savings and reduced lead times. These deals are just one way to optimize your US Import Supply Chain: Reduce Lead Times by 15% with These Strategies.

Establishing Strategic Partnerships

Foster strong, collaborative relationships with key suppliers and carriers. Work together to identify opportunities for streamlining processes and reducing transit times. Shared goals can lead to innovative solutions that benefit all parties involved.

Securing Volume Discounts and Priority Handling

Negotiate volume discounts with carriers to lower transportation costs. Additionally, seek priority handling for your shipments to ensure they move through ports and customs quickly. These measures can result in substantial time and cost savings.

Building a close-knit association with the companies helping you import can lead to mutual long-term benefits.

Improving Customs Clearance Processes

Customs clearance is often a major bottleneck in the US import supply chain. Simplifying and expediting this process can significantly reduce lead times. There are a couple ways to manage this to optimize your US Import Supply Chain: Reduce Lead Times by 15% with These Strategies.

Pre-Arrival Review and Compliance

Submit documentation and information to customs authorities before your goods arrive in the US. This allows for pre-arrival review, potentially speeding up the clearance process. Ensuring compliance with all regulations is crucial to avoid delays and penalties.

Leveraging Automated Broker Interface (ABI)

Use ABI to electronically submit customs entries and receive real-time updates on the status of your shipments. This streamlines the clearance process and reduces the need for manual intervention. Getting the most up-to-date information is important.

- Accurate documentation: Ensure all paperwork is complete and correct to avoid delays.

- Proactive communication: Maintain open lines of communication with customs brokers.

- Utilizing Free Trade Agreements: Take advantage of preferential tariff rates where applicable.

Speeding up this area of the process can save you money and headaches in the long run.

Optimizing Inventory Management Strategies

Efficient inventory management is essential for reducing lead times and minimizing carrying costs. By implementing proven strategies, you can ensure that you have the right amount of stock on hand to meet demand without tying up excessive capital. And you can use this information to optimize your US Import Supply Chain: Reduce Lead Times by 15% with These Strategies.

Implementing Just-In-Time (JIT) Inventory

Adopt a JIT inventory system to minimize the amount of inventory you hold. This involves receiving goods only when they are needed, reducing storage costs and the risk of obsolescence. JIT requires close coordination with suppliers to ensure timely deliveries.

Using Demand Forecasting Techniques

Employ demand forecasting techniques to predict future demand accurately. This allows you to optimize your inventory levels, avoiding both stockouts and excess inventory. Accurate forecasting reduces the need for rush orders and expedited shipping.

Having the appropriate amounts of inventory requires a strong understanding of your current inventory needs.

Conclusion

Optimizing your US import supply chain requires a multifaceted approach that encompasses process improvements, technology adoption, strategic partnerships, and efficient inventory management. By implementing these strategies, you can achieve significant reductions in lead times, improve efficiency, and gain a competitive edge in the market. Embrace these practices to transform your import operations and drive long-term success.

| Key Point | Brief Description |

|---|---|

| ⏱️ Assess Lead Times | Track and analyze current lead times to identify bottlenecks. |

| 💻 Implement Tech | Use tracking systems and cloud platforms for real-time visibility. |

| 🤝 Negotiate Terms | Establish partnerships and secure volume discounts. |

| 📦 Optimize Inventory | Use JIT and demand forecasting to manage inventory. |

FAQ Section

▼

A supply chain is a network of organizations and resources that produce and deliver a product or service from raw materials to end customers. It involves various stages like sourcing, manufacturing, storage, and distribution to finally reach to the consumer.

▼

Lead times are the duration between when a process starts and when it concludes. This can pertain to an individual step, or relate to an entire process from the beginning to the end. Reducing lead times, therefore, is crucial to improve profits.

▼

A Supply chain optimization is very important because it can enhances efficiency, which reduces operational costs and improves profitability. Optimized supply chains typically improve the performance. So, it can be critical to your success.

▼

Tracking systems and cloud-based platforms enhance this, providing real-time data on inventory levels and shipment status. The information provided ensures proactive management, improving decision-making and collaboration among the parties invovled.

▼

JIT, or Just-In-Time, is an inventory system where materials and components are scheduled to arrive exactly when they are needed in the production process. Reducing inventory holding costs and minimizing waste are great added benefits of this methodology.

Conclusion

In conclusion, optimizing your US import supply chain is a crucial step towards enhanced efficiency and profitability. By implementing the strategies discussed, such as real-time visibility, better supplier and carrier terms, improved customs processes, and optimized inventory management, businesses can significantly reduce lead times and achieve a competitive edge.