Insider Report: The Rise of AI in Manufacturing – Opportunities & Risks in the US Market

Insider Report: The Rise of AI in Manufacturing – Opportunities and Risks explores how AI is revolutionizing US manufacturing, boosting efficiency and innovation, while also highlighting potential risks like job displacement and cybersecurity threats.

The manufacturing sector in the United States is undergoing a profound transformation, driven by the rapid advancements in artificial intelligence (AI). Insider Report: The Rise of AI in Manufacturing – Opportunities and Risks delves into this evolving landscape, exploring both the immense potential and the challenges that AI presents to manufacturers across the country.

From automating mundane tasks to optimizing entire supply chains, AI is reshaping how products are designed, produced, and delivered. However, alongside these exciting advancements come critical considerations around workforce readiness, ethical implications, and the ever-present threat of cybersecurity breaches. This report aims to provide a comprehensive overview of the opportunities and risks associated with the increasing adoption of AI in US manufacturing.

Understanding the AI Revolution in US Manufacturing

Artificial intelligence is no longer a futuristic concept; it’s a present-day reality reshaping industries worldwide. In the United States, the manufacturing sector is at the forefront of this revolution, with AI technologies being integrated into nearly every aspect of the production process. This section will explore some of the key ways AI is transforming manufacturing.

AI-Powered Automation

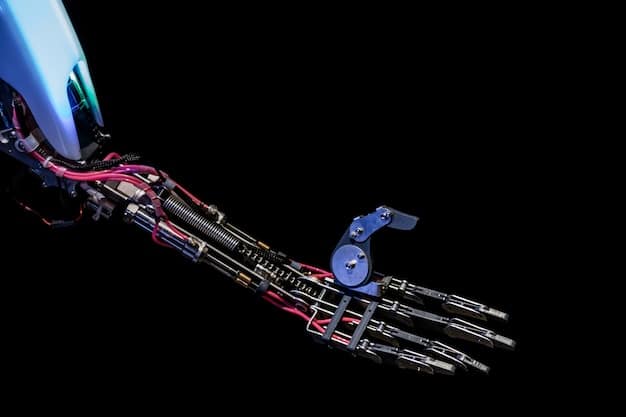

Automation has long been a cornerstone of manufacturing, and AI is taking it to the next level. AI-powered robots are capable of performing complex tasks with greater speed, accuracy, and consistency than their human counterparts.

Predictive Maintenance

Unexpected equipment failures can lead to costly downtime and disruptions in production. AI-driven predictive maintenance systems analyze data from sensors and other sources to identify potential issues before they occur, allowing manufacturers to schedule repairs and prevent breakdowns.

- Reduced downtime and increased productivity

- Lower maintenance costs through targeted repairs

- Improved equipment lifespan and reliability

AI is not just about automating physical tasks; it’s also about optimizing decision-making. AI algorithms can analyze vast amounts of data to identify patterns and trends, providing manufacturers with valuable insights that can inform everything from product design to inventory management.

The integration of AI into manufacturing is revolutionizing how factories are constructed and managed. As manufacturers throughout the US implement AI-powered predictive maintenance and other revolutionary processes and systems, they will be better equipped to deal with the day to day challenges and potential hurdles that they will face.

Insider Report: The Rise of AI in Manufacturing – Opportunities and Risks

The surge of AI in the manufacturing sector brings with it a wave of unprecedented opportunities. By leveraging AI technologies, businesses can unlock new levels of efficiency, innovation, and competitiveness. Some of these opportunities include:

Increased Efficiency and Productivity

AI-powered automation streamlines processes, minimizes errors, and optimizes resource utilization, leading to significant gains in efficiency and productivity.

Enhanced Product Quality

AI-driven quality control systems can detect even the slightest defects, ensuring that products meet the highest standards of quality and reducing the risk of recalls.

- Faster time-to-market for new products

- Improved customer satisfaction through higher quality products

- Reduced waste and rework

AI enables manufacturers to personalize products and services to meet the unique needs of individual customers. This can lead to increased customer loyalty and a competitive advantage.

Reduced Costs

By optimizing processes, reducing waste, and preventing equipment failures, AI can help manufacturers significantly reduce their operating costs.

Insider Report: The Rise of AI in Manufacturing – Opportunities and Risks is providing an increase in efficiency and a decrease in costs. However, these aren’t the only advantages that contribute to the shift in the manufacturing industry in the U.S. With AI becoming more present in daily operations, U.S. manufacturing businesses will likely only continue to grow both in revenue and productivity in the coming years.

Addressing the Risks of AI in Manufacturing

While the potential benefits of AI in manufacturing are undeniable, it’s crucial to acknowledge and address the risks associated with its adoption. This section will delve into some of the key challenges that manufacturers must navigate to ensure a successful and responsible integration of AI.

Job Displacement

One of the most significant concerns surrounding AI is its potential to displace human workers. As AI-powered robots and systems become more capable, many routine tasks that are currently performed by humans may be automated. This disruption can lead to job losses and create anxiety among the workforce.

Cybersecurity Threats

As manufacturing processes become increasingly reliant on digital systems and data, the risk of cyberattacks increases. AI systems can be vulnerable to hacking and malware, which can disrupt production, compromise sensitive data, and even cause physical damage to equipment.

- Implementing robust security measures, such as firewalls, intrusion detection systems, and data encryption

- Providing cybersecurity training to employees to raise awareness of potential threats

- Establishing incident response plans to quickly address any security breaches

AI systems are only as good as the data they are trained on. If the data is biased, the AI system will perpetuate and amplify those biases, leading to unfair or discriminatory outcomes.

Ethical Considerations

AI raises a number of ethical questions, such as who is responsible when an AI system makes a mistake? How do we ensure that AI is used in a way that is fair and equitable?

Effectively managing the challenges and potential risks associated with Insider Report: The Rise of AI in Manufacturing – Opportunities and Risks will bring the best possible solutions to bear for these manufacturing entities.

Strategies for Successful AI Implementation

To reap the full benefits of AI in manufacturing while mitigating the risks, companies need to adopt a strategic and well-planned approach. This section will outline some key strategies for successful AI implementation.

Developing a Clear AI Strategy

Before embarking on any AI project, manufacturers should develop a clear strategy that aligns with their overall business goals.

Investing in Workforce Training

To prepare the workforce for the age of AI, manufacturers need to invest in training programs that equip employees with the skills they need to work alongside AI systems.

Prioritizing Data Security

Protecting data is paramount. Manufacturers must implement robust security measures to safeguard their AI systems and data from cyber threats.

Companies need to prioritize cybersecurity threats to prevent hackers from accessing the digital systems related Insider Report: The Rise of AI in Manufacturing – Opportunities and Risks. Companies also want to invest in employee training, so that factory workers can be as well-equipped as possible to work alongside AI systems.

The strategies mentioned above are not all of the ways manufacturers can handle their integration of AI. As technology continues to advance, they will be able to use additional resources and processes to facilitate their manufacturing needs.

The Future of AI in US Manufacturing

The use of artificial intelligence is already showing significant improvements in U.S. manufacturing, and will continue to grow. This section will look to the future and consider what is to come from artificial intelligence in U.S. manufacturing

Continued Growth and Innovation

AI will continue to drive growth and innovation in the US manufacturing sector, as new applications and capabilities emerge.

Increased Collaboration Between Humans and AI

The future of manufacturing will be characterized by increased collaboration between humans and AI systems, with each leveraging their unique strengths.

- Robots can perform repetitive and dangerous tasks, freeing up humans to focus on more creative and strategic activities.

- AI-powered analytics can provide humans with insights and recommendations to improve decision-making.

The adoption of AI will lead to the emergence of new business models and revenue streams, as manufacturers leverage their AI capabilities to offer innovative products and services.

Focus on Ethical and Responsible AI

As AI becomes more prevalent, there will be an increasing focus on ensuring that it is used in an ethical and responsible manner.

Looking ahead, Insider Report: The Rise of AI in Manufacturing – Opportunities and Risks shows us a continued focus on the ethical and responsible implementation of AI in the manufacturing process. With further growth and innovation, there is almost no limit in sight for what can be improved in this industry.

| Key Point | Brief Description |

|---|---|

| 🤖 Increased Efficiency | AI-driven automation streamlines processes and optimizes resource use. |

| 🛡️ Cybersecurity Risks | AI systems are vulnerable to cyberattacks, requiring robust security measures. |

| 🧑🏭 Workforce Training | Training programs are crucial to equip workers with AI-related skills. |

Frequently Asked Questions

AI in manufacturing helps increase efficiency by automation of tasks, improves quality control through defect detection, enables faster time-to-market by optimizing processes, and reduces operational costs by predicting equipment failures.

Manufacturers can protect themselves by implementing strong security measures like firewalls, intrusion detection, and data encryption. It’s also important to provide regular cybersecurity training to employees to increase awareness of threats.

Manufacturing workers will need to develop skills in data analysis, AI system maintenance, and human-machine collaboration. Problem-solving, critical thinking, and adaptability will also be highly valued in AI-driven manufacturing environments.

AI algorithms analyze data from sensors to predict potential equipment failures, enabling manufacturers to schedule maintenance proactively, reduce downtime, and extend the lifespan of machinery, leading to cost savings and increased productivity.

Ethical considerations include addressing potential job displacement, ensuring data privacy, and mitigating biases in AI algorithms. Manufacturers should strive for transparency and fairness in the design and deployment of AI systems to promote responsible use.

Conclusion

In conclusion, the integration of AI into the US manufacturing sector presents both tremendous opportunities and significant risks. Insider Report: The Rise of AI in Manufacturing – Opportunities and Risks explores key areas like increased efficiency, cybersecurity concerns, and workforce adaptation.