Circular Economy in US: 6 Models & 20% Waste Reduction by 2028

Breaking news reveals that a powerful shift towards a Circular Economy in the US: 6 Business Models Projecting 20% Waste Reduction by 2028 (FINANCIAL IMPACT) is gaining significant traction, promising substantial environmental and economic benefits. This strategic pivot is set to redefine how industries operate and consume resources.

The Urgent Need for Circularity in the US

The United States faces an escalating waste crisis, with landfills rapidly reaching capacity and resource depletion becoming a critical concern. Traditional linear economic models, characterized by ‘take-make-dispose’ practices, are no longer sustainable. This growing pressure necessitates a fundamental rethinking of production and consumption patterns, driving the adoption of circular economy principles.

Recent analyses underscore the urgency, pointing to significant environmental degradation and economic inefficiencies linked to current practices. The transition to a circular economy is not merely an environmental imperative but also a strategic economic opportunity, fostering innovation, creating new jobs, and enhancing resource security. Businesses are increasingly recognizing the long-term value in moving away from a disposable culture.

Economic Drivers for Circular Models

- Resource Scarcity: Diminishing access to virgin materials drives up costs and incentivizes reuse.

- Regulatory Pressure: Evolving environmental regulations push companies towards sustainable practices.

- Consumer Demand: A growing segment of consumers prefers eco-friendly products and services.

- Innovation Opportunities: New technologies and business models emerge from circular design principles.

The financial implications of inaction are becoming clearer, with industries facing higher operational costs due to waste management and increased raw material prices. Embracing circularity offers a pathway to mitigate these risks while unlocking new revenue streams and building more resilient supply chains.

Understanding the Circular Economy Framework

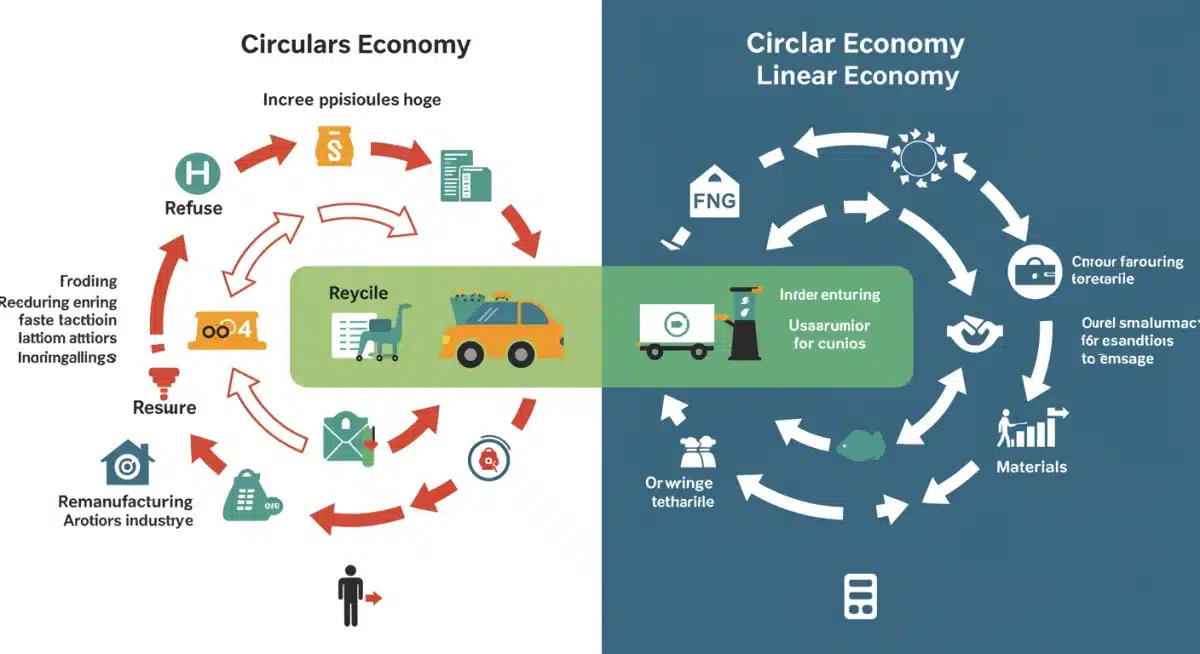

The circular economy represents a paradigm shift from linear models, aiming to keep products, components, and materials at their highest utility and value at all times. It is designed to regenerate natural systems, moving beyond simply reducing negative impacts to creating positive ones. This framework is built upon principles of waste and pollution prevention, product and material circulation, and natural system regeneration.

Unlike traditional approaches that focus on end-of-life solutions like recycling, the circular economy integrates sustainability from the very design stage. It encourages systemic thinking, involving every stage of a product’s lifecycle, from sourcing materials to consumption and eventual recovery. This holistic view is critical for achieving significant waste reduction targets and fostering true economic sustainability.

Core Principles of a Circular System

At its heart, the circular economy operates on three fundamental principles:

- Design out waste and pollution: This means rethinking how products are made and used to eliminate waste before it’s created.

- Keep products and materials in use: Maximizing the lifespan of products through reuse, repair, refurbishment, and remanufacturing.

- Regenerate natural systems: Returning biological materials to the earth and technical materials to the economy without harm.

These principles guide businesses in developing strategies that minimize environmental impact while maximizing economic value. The shift requires collaboration across supply chains, innovative design, and new business models that prioritize longevity and resource efficiency. The projected 20% waste reduction in the US by 2028 is directly linked to the widespread adoption and effective implementation of these core tenets.

Six Business Models Driving US Waste Reduction

As the circular economy gains traction in the US, six distinct business models are emerging as key drivers for achieving the ambitious 20% waste reduction target by 2028. These models represent innovative approaches to production, consumption, and material management, offering both environmental benefits and significant financial returns. Each model addresses different facets of the linear economy’s shortcomings, providing comprehensive solutions for resource optimization.

From businesses focused on extending product lifespans to those entirely redesigning material flows, these models are proving scalable and highly effective. They demonstrate a clear path for industries to transition towards more sustainable operations, contributing directly to the overarching goal of a more resilient and less wasteful economy. The successful implementation of these models critically depends on technological advancements, policy support, and consumer engagement.

1. Product-as-a-Service (PaaS)

The PaaS model shifts ownership from the consumer to the manufacturer, who retains responsibility for maintenance, repair, and end-of-life management. Consumers pay for the use or performance of a product, rather than owning it outright. This incentivizes manufacturers to design durable, repairable, and upgradable products, as their revenue is tied to product longevity and customer satisfaction.

Examples include:

- Subscription services for industrial equipment, tools, or even clothing.

- Leasing programs for electronics or appliances, ensuring materials are recovered and reused.

- Tire manufacturers offering mileage-based contracts, focusing on tire longevity and retreading.

This model significantly reduces waste by extending product lifespans and ensuring high-quality material recovery. The financial impact is seen in reduced raw material costs for manufacturers and predictable revenue streams.

2. Resource Recovery and Recycling

While traditional recycling is part of the linear economy, in a circular context, it focuses on high-quality material recovery and reprocessing to create new products. This model emphasizes advanced sorting technologies, innovative reprocessing techniques, and strong market demand for recycled content. It aims to transform waste into valuable secondary raw materials, closing material loops effectively.

Key aspects include:

- Advanced plastics recycling, including chemical recycling for harder-to-recycle polymers.

- Urban mining for valuable metals from electronic waste (e-waste).

- Composting and anaerobic digestion of organic waste to produce soil amendments and energy.

The financial benefit comes from reducing reliance on virgin resources and creating new markets for secondary materials, leading to cost savings and new revenue opportunities.

3. Repair, Refurbishment, and Remanufacturing

This model focuses on extending the life of products and components through repair, refurbishment, and remanufacturing processes. Instead of discarding items at the first sign of malfunction or obsolescence, they are restored to working condition or upgraded to meet current standards. This directly reduces the demand for new products and associated manufacturing impacts.

The growth of repair cafes, professional refurbishment services, and remanufacturing facilities for industrial machinery underscores the viability and growing importance of this approach. It also creates skilled jobs and fosters local economies. The financial upside includes significant cost savings for consumers and businesses, along with new service-based revenue streams for companies.

The Value of Extended Product Life

Extending product life offers multiple advantages:

- Reduced waste generation: Fewer products end up in landfills.

- Lower consumption of new resources: Decreased need for raw materials and energy for manufacturing.

- Cost savings for consumers: Repairing or buying refurbished is often cheaper than buying new.

- New business opportunities: Growth in repair services, spare parts supply, and specialized refurbishment.

The economic incentive is strong, as companies can capture value from products multiple times throughout their lifecycle, moving beyond a single transaction model.

4. Circular Sourcing and Sustainable Materials

This model emphasizes sourcing materials that are renewable, recyclable, biodegradable, or derived from waste streams. It involves designing products with materials that can be easily disassembled and reused or safely returned to the biosphere. The focus is on materials that maintain their quality and value through multiple cycles, reducing the need for virgin resources and minimizing environmental impact.

Innovation in material science is crucial here, leading to the development of bio-based plastics, advanced composites, and materials optimized for closed-loop recycling. Companies adopting this model are actively seeking alternatives to conventional, resource-intensive materials, building more resilient and sustainable supply chains from the ground up.

Innovations in Material Design

Significant progress is being made in:

- Bio-based materials: Utilizing agricultural waste or renewable biomass for packaging and products.

- Recycled content integration: Increasing the percentage of post-consumer or post-industrial recycled materials in new products.

- Design for disassembly: Creating products where components can be easily separated for repair or recycling.

The financial benefits include reduced material costs in the long run, enhanced brand reputation, and compliance with future environmental standards, all contributing to the overall success of the Circular Economy in the US: 6 Business Models Projecting 20% Waste Reduction by 2028 (FINANCIAL IMPACT).

5. Sharing Platforms and Collaborative Consumption

Sharing platforms enable multiple users to access and utilize products or assets without individual ownership. This model maximizes the utilization rate of goods, reducing the overall number of products needed to satisfy demand. Examples range from car-sharing services to tool libraries and peer-to-peer lending platforms for various items. By sharing, the environmental footprint associated with manufacturing, transporting, and disposing of numerous individual products is significantly reduced.

Collaborative consumption fosters a community-driven approach to resource efficiency, where access is prioritized over ownership. This not only leads to waste reduction but also offers economic benefits for consumers through reduced personal expenses and for businesses by optimizing asset utilization. The digital infrastructure supporting these platforms is crucial for their scalability and widespread adoption across urban and rural areas alike.

Benefits of Collaborative Consumption

- Increased product utilization: Fewer items sit idle, increasing their functional lifespan.

- Reduced individual consumption: Consumers buy fewer goods, leading to less waste.

- Cost savings for users: Accessing items is often cheaper than buying them.

- Community building: Fosters local connections and resource sharing.

These platforms represent a powerful shift in consumer behavior, demonstrating that value can be derived from products without perpetual ownership, aligning perfectly with the goals of a circular economy. The financial impact extends to new market creation and improved resource efficiency.

6. Waste-to-Value Transformation

The waste-to-value model focuses on transforming waste streams into new, high-value products or energy. This goes beyond traditional recycling by innovating processes that convert complex waste materials into resources for other industries. It includes advanced technologies such as pyrolysis, gasification, and fermentation, which break down waste into basic components that can then be re-engineered into new materials or fuels.

This model is particularly impactful for difficult-to-recycle waste streams, offering solutions where conventional methods fall short. By creating value from what was once considered waste, it reduces landfill dependency and generates new revenue streams. The financial impact is substantial, turning a cost center (waste disposal) into a profit center (resource production), accelerating progress towards a robust Circular Economy in the US: 6 Business Models Projecting 20% Waste Reduction by 2028 (FINANCIAL IMPACT).

Innovative Waste Conversion Technologies

Key technologies include:

- Chemical recycling of plastics: Breaking down polymers into monomers for new plastic production.

- Bio-refineries: Converting organic waste into biochemicals, biofuels, and bioplastics.

- Industrial symbiosis: Where one industry’s waste becomes another’s raw material, creating localized circular loops.

These transformations not only mitigate environmental impact but also foster industrial innovation and economic growth, positioning the US as a leader in sustainable resource management.

| Business Model | Description & Impact |

|---|---|

| Product-as-a-Service | Customers pay for product use, not ownership. Incentivizes durability, repair, and reduces waste. |

| Resource Recovery | High-quality recycling and reprocessing of materials into new products, reducing virgin resource demand. |

| Repair & Remanufacturing | Extends product lifespan through repair, refurbishment, and remanufacturing, minimizing new production. |

| Waste-to-Value | Transforms complex waste streams into new, high-value products or energy, reducing landfill dependency. |

Frequently Asked Questions on Circular Economy in the US

The primary goal is to achieve a 20% reduction in waste by 2028 through the widespread adoption of circular business models. This initiative aims to minimize landfill reliance, conserve natural resources, and foster sustainable economic growth across various sectors.

These models generate financial impact by reducing raw material costs, creating new revenue streams from secondary materials, optimizing asset utilization, and enhancing brand value. They also foster innovation and create new job opportunities in repair, remanufacturing, and resource recovery sectors.

PaaS involves customers paying for product use rather than ownership. Manufacturers retain ownership, incentivizing them to design durable, repairable products. This model extends product lifespans, reduces premature disposal, and ensures materials are recovered efficiently at the end of use, drastically cutting waste.

Yes, sharing platforms are a key component. They maximize product utilization by allowing multiple users to access goods without individual ownership. This reduces the overall demand for new products, decreases manufacturing impacts, and minimizes waste generated from underutilized items, promoting efficient resource use.

Waste-to-value transformation converts waste streams into new high-value products or energy, moving beyond traditional recycling. It utilizes advanced technologies to reprocess complex waste into resources for other industries, reducing landfill dependency and creating new economic opportunities from previously discarded materials.

What Happens Next

The trajectory towards a Circular Economy in the US: 6 Business Models Projecting 20% Waste Reduction by 2028 (FINANCIAL IMPACT) is set to accelerate, with continued innovation and collaboration crucial for sustained progress. Expect to see increased policy support, further investment in circular infrastructure, and a growing consumer awareness driving demand for sustainable products and services. The coming months will likely feature more partnerships between businesses, government entities, and research institutions, all working to embed circular practices deeper into the national economic fabric. This transition is not merely about waste management; it’s about building a more resilient, resource-efficient, and economically stable future for the United States.